Overview: Weihai Create Filtration Fan Co., Ltd. is a high-tech enterprise established in 2001, specializing in the design, research and development, production and manufacturing of ventilation and air treatment system equipment and accessories such as ventilators and ventilation cooling systems. Its main business is engaged in the research and development, production, sales and related maintenance services of ventilation equipment products and systems in the mid-to-high-end equipment industries such as rail transit ventilation cooling equipment, energy ventilation cooling equipment, marine engineering and ship fans, cooling tower and air cooler fans, and refrigeration fans.

GZ DP Anechoic T&E Co., Ltd. is composed of a team of acoustic experts and professional engineers who have been engaged in various acoustic technology research at home and abroad for many years and have rich theoretical and practical experience. It owns its own office building and factory, and an acoustic laboratory that complies with the CNAS standard has been built in the factory, which can monitor the acoustic technical indicators of its own products and provide external acoustic testing services. The semi-anechoic chamber is not only a special laboratory for acoustic testing but also an important part of the testing system. In fact, it is also one of the acoustic testing equipment, and its acoustic performance indicators directly affect the accuracy of the test. For subsequent materials like simple introductions about the specific acoustic design, manufacturing, construction, installation and on-site actual measurement and acceptance of soundproof chambers, anechoic chambers, quiet chambers, reverberation chambers, semi-soundproof chambers, semi-anechoic chambers, fully soundproof chambers and fully anechoic chambers, please pay attention to browsing the project cases on the official website of the company we belong to, or scan the QR code of the WeChat public service account of the company we belong to to get free push notifications. For detailed information on soundproof chambers, anechoic chambers, quiet chambers, reverberation chambers, semi-soundproof chambers, semi-anechoic chambers, fully soundproof chambers and fully anechoic chambers, please go to the download center on the official website of the company we belong to to download them for free.

Keywords:Acoustic Laboratory ,Acoustic room;Anechoic chamber,Anechoic room;Semi-anechoic chamber,Semi-anechoic room;Hemi-anechoic chamber,Hemi-anechoic room;Fully anechoic chamber,Fully anechoic room;Professional anechoic chamber;Professional semi-anechoic chamber ,Professional hemi-anechoic chamber;Professional full anechoic chamber ;soundproof room (sound insulation room, soundproof chamber, silent room);Sound insulation box;reverberation chamber;Listening room (listening chamber, sound listening room);Anechoic room (noiseless room);Silent room (soundproof room),Noise-proof room;Noise room (noise chamber),Noise generation room;Airborne sound insulation laboratory;Floor impact sound insulation laboratory;Automotive NVH laboratory;acoustic measuring instruments;vibration measuring instruments;Semi-anechoic chamber plan / Scheme for semi-anechoic chamber;Acoustic Testing Equipment,Acoustic Test Devices;Anechoic chamber manufacturers;Acoustic Engineering,Acoustical Engineering;Institute of Acoustics;Semi-anechoic chamber design;Fullanechoic chamber design;Online sound insulation chamber,Online acoustic isolation chamber.

I. Procurement Content

Semi-anechoic chamber

II. Standards Followed

1. GB/T 6882 "Acoustics - Determination of sound power levels of noise sources - Precision methods for anechoic and hemi-anechoic rooms"

2. ISO 3745 "Acoustics - Determination of sound power levels of noise sources - Precision methods for anechoic and hemi-anechoic rooms"

3. JJF 1147 "Calibration Specification for Acoustic Characteristics of Anechoic and Hemi-anechoic Rooms"

4. GB/T 34877.3 - 2017 "Industrial fans - Determination of fan sound power under standard laboratory conditions - Part 3: Enveloping surface method"

5. GB/T 1236 - 2017 "Industrial fans - Performance testing using standardized air ducts"

6. GB 50034 - 2004 "Standard for lighting design of buildings"

III. Project Content and Main Indicators

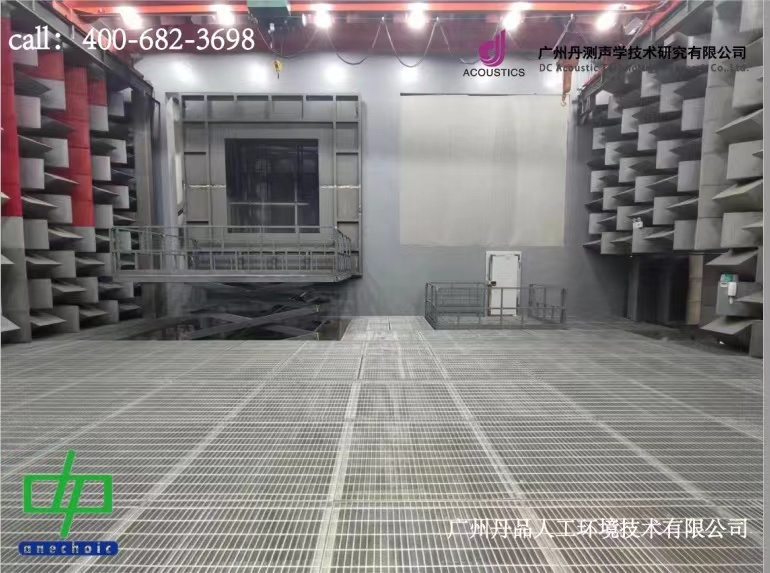

1. The effective net internal dimensions of the semi-anechoic chamber installation project: 15000mm × 15100mm × 11300mm, with an accuracy of +/- 100mm;

2. The size of the sound-absorbing and noise-reducing wedges used in the semi-anechoic chamber: 600 * 600 * 1000mm; when the external environment is working normally and there is no abnormal interference around (such as ground pounding, piling, impact), the background noise Lgn(A) ≤ 30dB(A), and the cut-off frequency: Fc ≤ 63Hz. IV. Key and Difficult Points of the Project

1. Wind Tunnel Pipeline

In order to reduce the impact of the noise generated when air enters the internal circulation on the semi-soundproof chamber and ensure that the background noise in the semi-soundproof chamber remains unchanged, the project has also carried out a unique design on the ventilation pipeline. The outer plate of the air duct adopts hot-dip galvanized copper plate, and a professional sound-absorbing and noise-reducing perforated flat plate is installed inside to reduce the noise generated when air flows. Sound-absorbing and noise-reducing materials are installed inside the pipeline to effectively ensure the treatment of sound absorption and noise reduction in the pipeline. At the same time, the pipeline is also equipped with sound-absorbing protective films to effectively prevent the leakage of dust generated by the sound-absorbing and noise-reducing materials and avoid the adverse impact of dust on the health of indoor workers. Another highlight of the pipeline design is to change the traditional pipeline interface method, adopt the method of connecting the auxiliary fan and the air duct with a round-to-square reducer and adding a flexible connection to reduce the vibration transmission of the auxiliary fan.

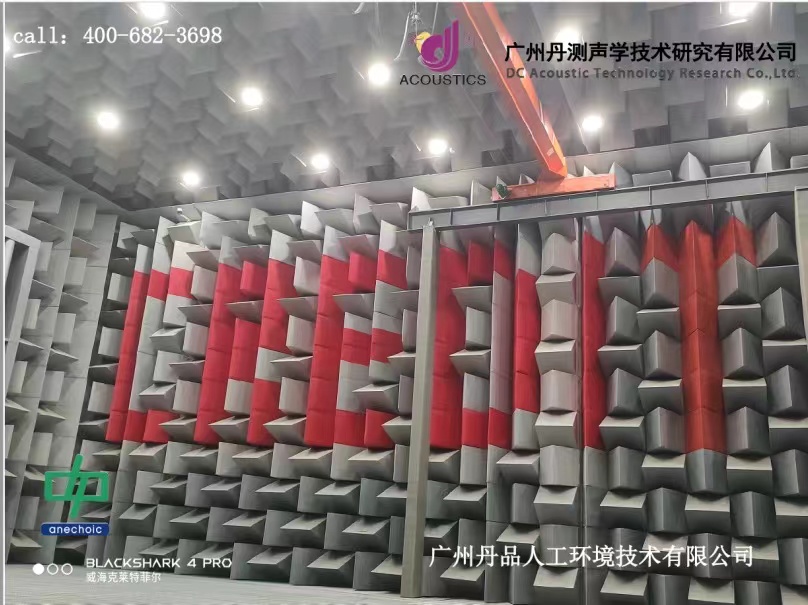

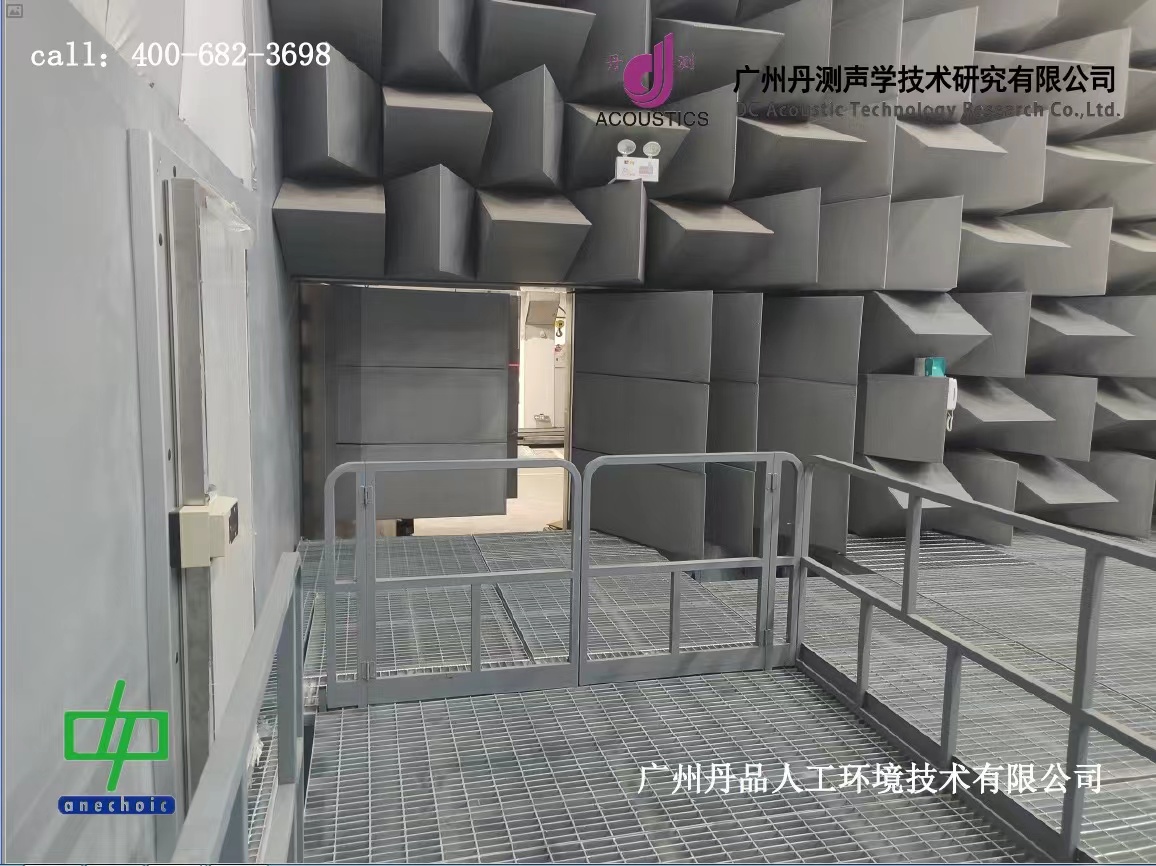

2. Movable Wedge Module Structure

In order to facilitate the replacement of test fans, a movable wedge area is installed in the semi-soundproof chamber. A group of movable wedge modules with moving wheels are installed under the movable wedge area. When replacing the test fan, open the acoustic gate, and the movable wedges with moving wheels move from the inside to the outside through the door. After the test fan is replaced, move the movable wedge modules back to their original positions, close the acoustic gate, and the semi-anechoic chamber can resume normal use.

3. Lifting Platform

Two manned lifting platforms are installed inside the semi-soundproof chamber. One of them adopts a hydraulic scissor self-propelled vehicle lifting platform, and the other adopts a fixed hydraulic scissor lifting platform. Both lifts have undergone sound-absorbing and noise-reducing treatment to avoid the impact of the noise generated during the operation of the machines on the indoor background noise. Mobile wedge modules are used in the lifting platform area. When the lifting platform is moved out, the ground part of the lifting platform area can be filled to form a unified flat ground network structure indoors.

4. Noise and Vibration Testing Instrument System

The noise and vibration testing instrument system installed in the semi-anechoic chamber refers to GB/T 34877.3 - 2017 "Industrial fans - Determination of fan sound power levels under standard laboratory conditions", GB/T 1236 - 2017 "Industrial fans - Performance testing using standardized air ducts" and GB/T 3767 - 2016 "Acoustics - Determination of sound power levels of noise sources using sound pressure method - Engineering method for an approximately free field above a reflecting plane". This system can be used for fan sound power testing, noise analysis testing, including time-domain signal analysis, CPB analysis, FFT analysis and other weighting methods, with a total of 12 channels. The microphones used in the semi-anechoic chamber can meet the international and domestic testing standards for fans, as well as preamplifiers and sound level calibrators.

IV. Measurement and Acceptance

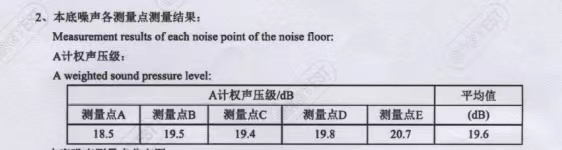

The actually measured background noise is: Lgn(A) ≤ 19.6dB (A).

V. Project Results

For more specific content, you are welcome to call for consultation or scan the QR code below to get more information about our company.